C Series

CT (CTC, CTE, CTF, 100CFC/CFE/CFF)

Applications

- General industrial applications

- Petrochemical industrial

- Pharmaceutical and food industrial

- Chemical industrial

Features

- Due to selection of material combinations in Staianless

steel and PTFE, it can target variety of applications such like

solvent, chemical, pure water or petrochemical liquid

Easy maintenanace is possible without removing piping

due to B.P.O (Back-Pull-Out) design had been applied. - High performance, compact in size and low NPSH design.

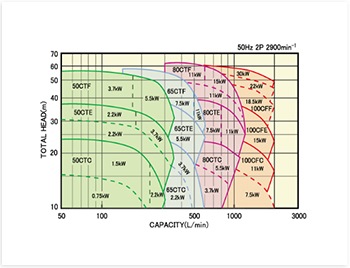

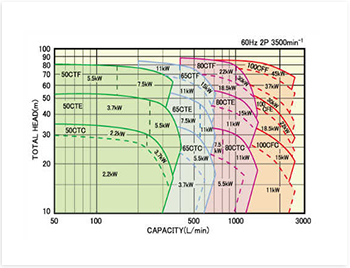

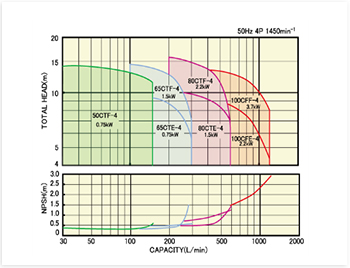

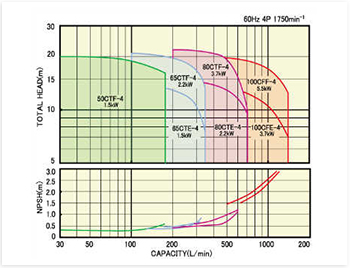

Performance Curve

Performance Curve

Specification data

| Series name | CT | CT-K |

| Total head | Max. 85 m | |

| Flow rate | Max. 1400 L/min | |

| Liquid temperature | ~ 80℃ | ~ 150℃ (oil) / ~ 120℃ (water) |

Material

| Series name | CT | CT-K |

| Casing & cover | SCS13 | |

| Impeller | SCS13 | |

| Mechanical seal | Ceramic – Carbon, PTFE | WC – Carbon, PTFE |

| O-ring | PTFE | FKM |

| Shaft | SS304 | |

Special specification for mechanical seal and packing

Tungsten carbide – Carbon, PTFE with seal marking of “-K”

Tungsten carbide – Tungsten carbide, PTE with seal marking of “-W”

SiC – SiC, PTFE (Double seals configuration)

Special specification for structure

Oil bath lubrication, Quenching, Cooling, External flushing and special standard flange .

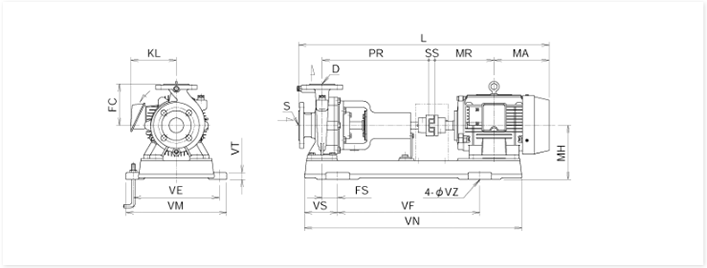

Dimensions