SN / SNW

Applications

- General industrial applications

- Pure water and chemical liquid supply

- Washing solvent supply, suitable for filtration applications

Features

-

No metal contact between the impeller and the

casing and cover, eliminating wear and

reducing contamination

Simple robust structure with minimal consumable parts,

suitable for processes requiring high reliability

Due to selection of material combinations (SUS304 /

PTFE / SiC) can target variety of applications

Very low noise levels silimar to centrifugal pumps,

additional noise reduction measures not required

Performance Curve

Specification data

| Series name |

KP-V | KH-V |

| Total Head | Max. 75 m | Max. 110 m |

| Flow rate | Max. 140 L/min | Max. 90 L/min |

| Liquid temp. | -20 to 120℃ (Standard) -20 to 150℃ (-V) |

|

| Connection | Special flange (Rc thread ) | |

Material

| Casing / cover |

CAC406 | |

| Impeller | CAC406 / SS304 | SS403 |

| Mechanical seal | SiC – Carbon, NBR (standard) SiC – Carbon, FKM (-V) |

|

| O-ring | NBR (standard) / FKM (-V) | |

| Shaft | SS304 | |

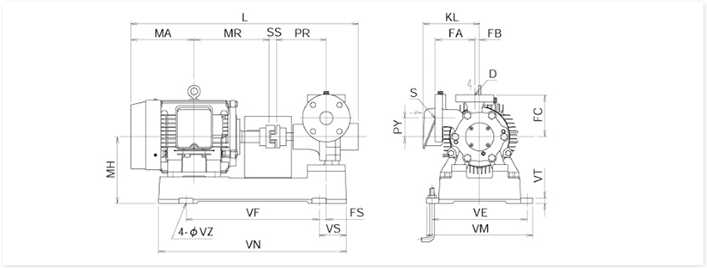

Dimensions

| Model | kW | S | D | PR | PY | FA | FB | FS | FC | MH | L | MA | MR | SS | VE | VF | VM | VN | VS | VT | VZ | KL | Weight |

| 15KP-V | 0.4 | Rc 1/2 | Rc 1/2 | 204 | 57 | 70.5 | 18 | 101 | 93 | 130 | 492 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | – | 18 |

| 20KP-V | 0.4 | Rc 3/4 | Rc 3/4 | 203 | 66 | 76 | 21 | 100 | 106 | 130 | 497 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | – | 20 |

| 0.75 | Rc 3/4 | Rc 3/4 | 203 | 66 | 76 | 21 | 100 | 106 | 130 | 518 | 122 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 27 | |

| 25KP-V | 0.75 | Rc 1 | Rc 1 | 208 | 75 | 86 | 24 | 107 | 122 | 140 | 527 | 122 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 27 |

| 1.5 | Rc 1 | Rc 1 | 208 | 75 | 86 | 24 | 114 | 122 | 150 | 592 | 155 | 167 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 36 | |

| 32KP-V | 1.5 | Rc 1 1/4 | Rc 1 1/4 | 208 | 82 | 92 | 26 | 113 | 133 | 150 | 596 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 37 |

| 2.2 | Rc 1 1/4 | Rc 1 1/4 | 208 | 82 | 92 | 26 | 113 | 133 | 150 | 596 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 42 | |

| 40KP-V | 1.5 | Rc 1 1/2 | Rc 1 1/2 | 207 | 84 | 94 | 27 | 112 | 136 | 150 | 598 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 37 |

| 1.5 | Rc 1 1/2 | Rc 1 1/2 | 207 | 84 | 94 | 27 | 112 | 136 | 150 | 598 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 42 |

ST / STS / STW / STWS

Applications

- General industrial applications

- Pure water and chemical liquid supply

- Washing solvent supply, suitable for filtration applications

Features

-

No metal contact between the impeller and the casing

and cover, eliminating wear and reducing contamination

Simple robust structure with minimal consumable parts,

suitable for processes requiring high reliability

Due to selection of material combinations

(SUS304 / PTFE / SiC) can target variety of applications

Very low noise levels silimar to centrifugal pumps,

additional noise reduction measures not required

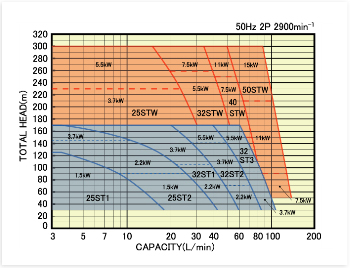

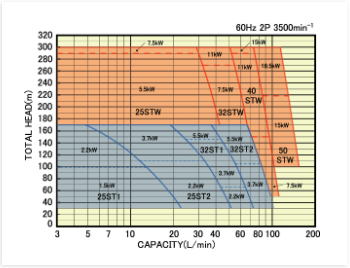

Performance Curve

Specification data

| Series name | ST | STS | STW | STWS |

| Total head | Max. 170 m | Max. 110 m | ||

| Flow rate | Max. 105 L/min | Max. 110 L/min | ||

| Liquid temperature | ~ 90℃ | ~ 100℃ | ~ 90℃ | ~ 100℃ |

| Connection | Suction: JIS 10K , Discharge: JIS 20K | Rc thread | ||

Material

| Series name | ST | STS | STW | STWS |

| Casing & cover | FC200 | |||

| Impeller | CAC406 | SS403 | CAC406 | SS403 |

| Mechanical seal | Ceramic – Carbon | SiC- Carbon | Ceramic – Carbon | SiC- Carbon |

| O-ring | NBR | FKM | NBR | FKM |

| Shaft | SS420J2 | |||

Dimensions

| Model | kW | S | D | PR | PY | FA | FB | FS | FC | MH | L | MA | MR | SS | VE | VF | VM | VN | VS | VT | VZ | KL | Weight |

| 25ST-1 | 2.2 | 25A | 20A | 128 | 50 | 104 | 13 | 0 | 110 | 145 | 533 | 155 | 168 | 20 | 230 | 350 | 260 | 500 | 75 | 15 | 12 | 156 | 50 |

| 25ST-2 | 3.7 | 25A | 20A | 128 | 50 | 104 | 13 | -30 | 110 | 180 | 616 | 186 | 200 | 20 | 280 | 425 | 310 | 616 | 96 | 25 | 12 | 175 | 66 |

| 32ST-1 | 5.5 | 32A | 25A | 128 | 50 | 110 | 15 | -15 | 122 | 204 | 690 | 211 | 239 | 30 | 324 | 448 | 354 | 690 | 121 | 25 | 12 | 212 | 101 |

| 32ST-2 | 5.5 | 32A | 25A | 128 | 78 | 115 | 20 | -15 | 139 | 204 | 690 | 211 | 239 | 30 | 324 | 448 | 354 | 690 | 121 | 25 | 12 | 212 | 101 |

| 32ST-3 | 5.5 | 32A | 25A | 128 | 78 | 115 | 20 | -15 | 139 | 177 | 690 | 211 | 239 | 30 | 324 | 448 | 354 | 690 | 121 | 25 | 12 | 212 | 103 |

SP

Applications

- General industrial applications

- Pure water and chemical liquid supply

- Washing solvent supply, suitable for filtration applications

Features

- No metal contact between the impeller and the casing and cover, eliminating wear and reducing contamination

- Simple robust structure with minimal consumable parts, suitable for processes requiring high reliability

- Due to selection of material combinations (SUS304 / PTFE / SiC) can target variety of applications

- Very low noise levels silimar to centrifugal pumps, additional noise reduction measures not required

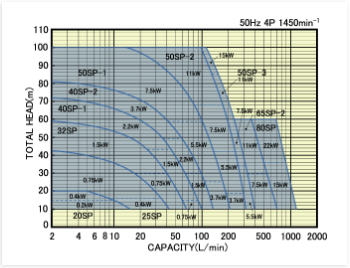

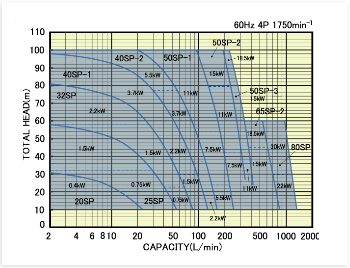

Performance Curve

Specification

| Series name |

SP | |

| Total Head | Max. 100 m | |

| Flow rate | Max. 1200 L/min | |

| Liquid temperature | ~90 ℃ (Standard) | |

| Connection | JIS 10K | |

Material

| Casing / cover | SCS13 | |

| Impeller | SS304 | |

| Mechanical seal |

20~40SP : Ceramic – Carbon |

|

| O-ring | PTFE | |

| Shaft | SS304 | |

Special specification

- Mechanical seal with the material of Tsungten carbide – Carbon or Tsungten carbide – Tsungten carbide availabe for 20SP to 50SP

- Mechanical seal with the material of SiC – Carbon or SiC – SiC / Carbon available for 65SP to 80SP Tsungten carbide – Tsungten carbide availabe for 20SP to 50SP

- Standard accessories : Coupling, base-plate, coupling guard

U Series

Applications

- General industrial applications

- Pure water and chemical liquid supply

- Washing solvent supply, suitable for filtration applications

Features

- Due to selection of material combinations (SUS304 /

PTFE / SiC) can target variety of applications - Very low noise levels silimar to centrifugal pumps,

- additional noise reduction measures not required

- Self-priming over 8 meters (25 feet)

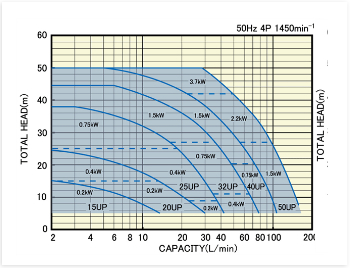

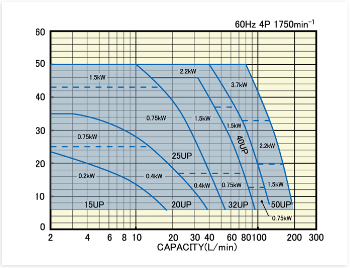

Performance Curve

Specification data

| Series name |

UP | |

| Total Head | Max. 50 m | |

| Flow rate | Max. 200 L/min | |

| Liquid temperature | ~90 ℃ | |

| Connection | JIS 5K (Rc Thread) | |

Material

| Casing / cover | SCS13 | |

| Impeller | SS304 | |

| Mechanical seal | SiC -SiC, PTFE | |

| O-ring | PTFE | |

| Shaft | SS304 | |

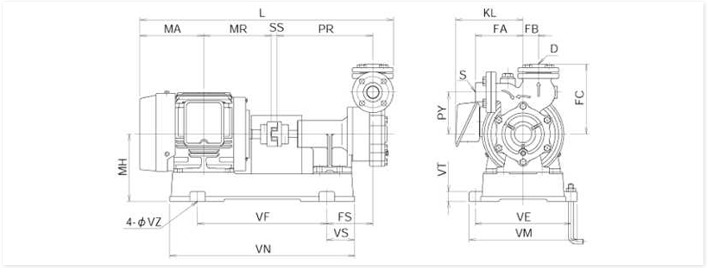

Dimensions

| Model | kW | S | D | PR | PY | FA | FB | FS | FC | MH | L | MA | MR | SS | VE | VF | VM | VN | VS | VT | VZ | KL | Weight |

| 15UP | 0.2 | 15A | 15A | 192 | 83 | 93 | 30 | 91 | 135 | 115 | 457 | 109 | 103 | 14 | 170 | 220 | 196 | 335 | 57 | 12 | 12 | 98 | 16 |

| 20UP | 0.4 | 20A | 20A | 198 | 87 | 99 | 32 | 94 | 146 | 130 | 495.5 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | 107 | 25 |

| 25UP | 0.75 | 25A | 25A | 197 | 96 | 107 | 35 | 95 | 159 | 140 | 538.5 | 140 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 36 |

| 32UP | 1.5 | 32A | 32A | 194 | 105 | 117 | 38 | 99 | 175 | 150 | 592.5 | 154.5 | 168.5 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 44 |

| 40UP | 2.2 | 40A | 40A | 237 | 110 | 120 | 40 | 100 | 183 | 165 | 688 | 178 | 193 | 20 | 280 | 425 | 310 | 610 | 92.5 | 25 | 12 | 156 | 59 |

| 50UP | 3.7 | 50A | 50A | 235 | 118 | 128 | 43 | 98.5 | 196 | 177 | 706 | 186 | 200 | 20 | 280 | 425 | 310 | 610 | 92.5 | 25 | 12 | 175 | 72 |

N Series

NP / NH-V

Applications

-

General industrial applications

Circulation of hot and cold water /media

Integrated with a variety of OEM machines

Pure water and chemical liquid supply

–

Features

-

Stable and reliable performance at small flow rates

Suitable for handling a variety of liquids including

pure water and various chemicals

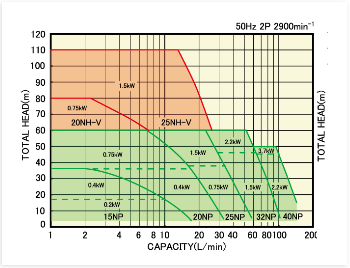

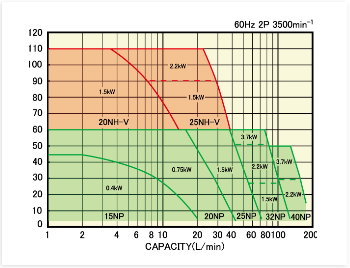

Performance Curve

Specification data

| Series name |

NP | NH-V |

| Total Head | Max. 60 m | Max. 110 m |

| Flow rate | Max. 160 L/min | Max. 50 L/min |

| Liquid temp. | ~90 ℃ | ~150 ℃ |

| Connection | Rc thread | |

Material

| Casing / cover |

SCS13 | SCS14 |

| Impeller | SS304 | SS316 |

| Mech. seal | SiC -SiC, PTFE | SiC – Carbon, FKM |

| O-ring | PTFE | FKM |

| Shaft | SS304 | SS316 |

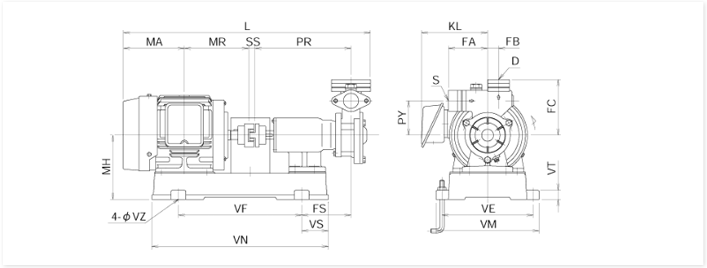

Dimensions

| Model | kW | S | D | PR | PY | FA | FB | FS | FC | MH | L | MA | MR | SS | VE | VF | VM | VN | VS | VT | VZ | KL | Weight |

| 15NP | 0.4 | Rc 1/2 | Rc 3/8 | 219 | 52 | 45 | 21 | 115 | 81 | 130 | 505 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | – | 18 |

| 20NP | 0.4 | Rc 3/4 | Rc 1/2 | 218 | 63 | 50 | 25 | 114 | 95 | 130 | 505 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | – | 20 |

| 0.75 | Rc 3/4 | Rc 1/2 | 218 | 63 | 50 | 25 | 116 | 95 | 140 | 526 | 122 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 27 | |

| 25NP | 0.75 | Rc 1 | Rc 3/4 | 224 | 70 | 60 | 28 | 122 | 105 | 140 | 539 | 122 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 27 |

| 1.5 | Rc 1 | Rc 3/4 | 224 | 70 | 60 | 28 | 129 | 105 | 150 | 604 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 37 | |

| 32NP | 1.5 | Rc 1 1/4 | Rc 1 | 224 | 80 | 65 | 35 | 129 | 120 | 150 | 609 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 37 |

| 2.2 | Rc 1 1/4 | Rc 1 | 224 | 80 | 65 | 35 | 129 | 120 | 150 | 609 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 42 | |

| 40NP | 2.2 | Rc 1 1/2 | Rc 1 1/4 | 238 | 85 | 70 | 40 | 123 | 130 | 145 | 629 | 155 | 169 | 18 | 230 | 350 | 260 | 500 | 75 | 15 | 12 | 156 | 45 |

| 3.7 | Rc 1 1/2 | Rc 1 1/4 | 238 | 85 | 70 | 40 | 82 | 130 | 180 | 692 | 186 | 200 | 18 | 280 | 425 | 310 | 616 | 96 | 25 | 12 | 175 | 61 |

K Series

KP-V / KH-V

Applications

- General industrial applications

- Circulation of hot and cold water /media

- Integrated with a variety of OEM machines

Features

- No rusting due to the cast bronze and stainless steel pump components

- Stable and reliable performance at small flow rates

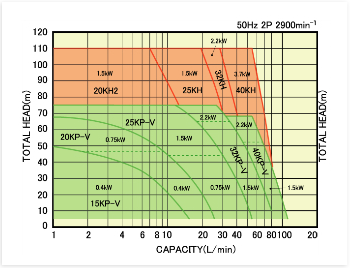

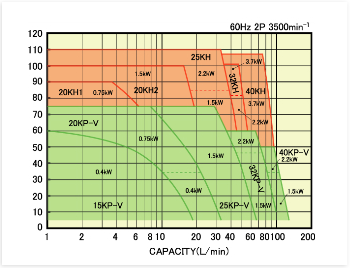

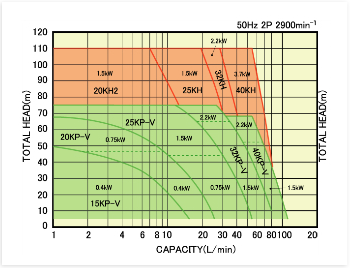

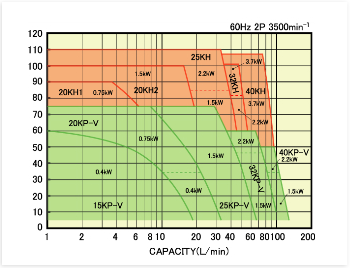

Performance Curve

Specification data

| Series name |

KP-V | KH-V |

| Total Head | Max. 75 m | Max. 110 m |

| Flow rate | Max. 140 L/min | Max. 90 L/min |

| Liquid temp. | -20 to 120℃ (Standard) -20 to 150℃ (-V) |

|

| Connection | Special flange (Rc thread ) | |

Material

| Casing / cover |

CAC406 | |

| Impeller | CAC406 / SS304 | SS403 |

| Mechanical seal | SiC – Carbon, NBR (standard) SiC – Carbon, FKM (-V) |

|

| O-ring | NBR (standard) / FKM (-V) | |

| Shaft | SS304 | |

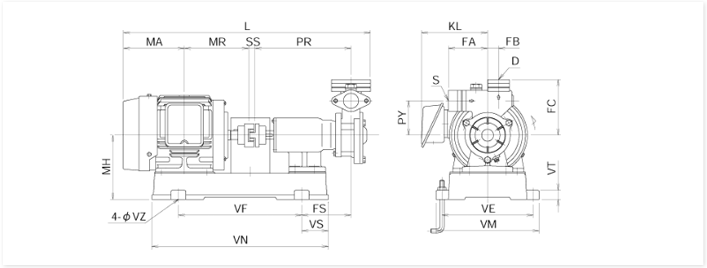

Dimensions

| Model | kW | S | D | PR | PY | FA | FB | FS | FC | MH | L | MA | MR | SS | VE | VF | VM | VN | VS | VT | VZ | KL | Weight |

| 15KP-V | 0.4 | Rc 1/2 | Rc 1/2 | 204 | 57 | 70.5 | 18 | 101 | 93 | 130 | 492 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | – | 18 |

| 20KP-V | 0.4 | Rc 3/4 | Rc 3/4 | 203 | 66 | 76 | 21 | 100 | 106 | 130 | 497 | 121 | 120 | 14 | 184 | 245 | 210 | 357 | 56 | 20 | 12 | – | 20 |

| 0.75 | Rc 3/4 | Rc 3/4 | 203 | 66 | 76 | 21 | 100 | 106 | 130 | 518 | 122 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 27 | |

| 25KP-V | 0.75 | Rc 1 | Rc 1 | 208 | 75 | 86 | 24 | 107 | 122 | 140 | 527 | 122 | 140 | 14 | 199 | 269 | 225 | 385 | 58 | 20 | 12 | 146 | 27 |

| 1.5 | Rc 1 | Rc 1 | 208 | 75 | 86 | 24 | 114 | 122 | 150 | 592 | 155 | 167 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 36 | |

| 32KP-V | 1.5 | Rc 1 1/4 | Rc 1 1/4 | 208 | 82 | 92 | 26 | 113 | 133 | 150 | 596 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 37 |

| 2.2 | Rc 1 1/4 | Rc 1 1/4 | 208 | 82 | 92 | 26 | 113 | 133 | 150 | 596 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 42 | |

| 40KP-V | 1.5 | Rc 1 1/2 | Rc 1 1/2 | 207 | 84 | 94 | 27 | 112 | 136 | 150 | 598 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 37 |

| 1.5 | Rc 1 1/2 | Rc 1 1/2 | 207 | 84 | 94 | 27 | 112 | 136 | 150 | 598 | 155 | 169 | 18 | 214 | 300 | 240 | 430 | 65 | 20 | 12 | 156 | 42 |

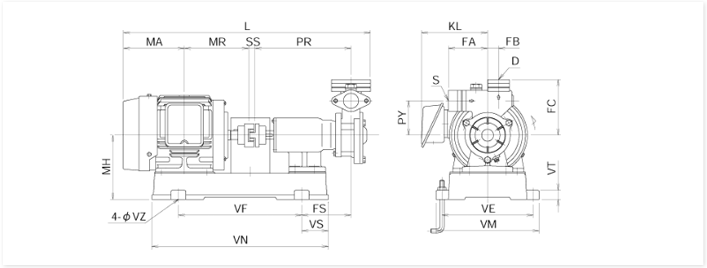

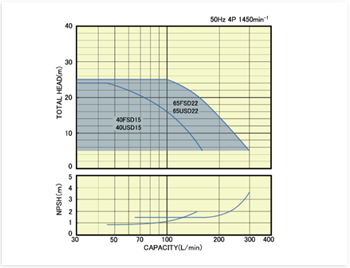

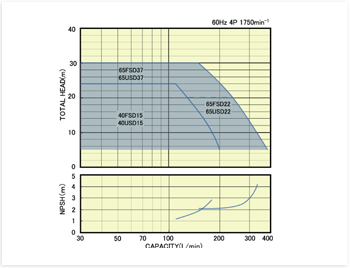

FSD / USD

Applications

- General industrial applications

- Integrated with a variety of OEM machines

- Suitable for filtration

Features

- Possible to install filter at pump suction side

and clean filter by running pump in reverse rotation

Low NPSH design - Cast iron and stainless steel lineup to

handle a variety of liquids

Performance Curve

Specification

| Series name |

FSD | USD | ||

| Total head | Max. 30 m | |||

| Flow rate | Max. 300 L/min | |||

| Liquid temp. | ~ 120 ℃ | |||

| Connection | JIS 5 K | |||

Material

| Series | FSD | USD |

| Casing / cover |

FC200 | SCS13 |

| Impeller | SS403 | SS304 |

| Mechanical seal | SiC – Carbon, FKM | |

| O-ring | FKM | |

| Shaft | SS316 | |

| Motor | 50Hz 200V, 60Hz 200/220V 1.5 ~3.7kW IP44・Insu.class:F/PSE | |

Dimensions

| Model | kW | S | D | PR | PY | FA | FB | FC | MH | L | MA | ME | MF | MM | MN | MZ | VT | KL | Weight |

| 40FSD15Z | 1.5 | 40A | 40A | 189.5 | 90 | 95 | 36 | 145 | 90 | 404 | 154.5 | 140 | 125 | 176 | 149 | 10×12 | 10 | 156 | 39.5 |

| 65FSD22Z | 2.2 | 65A | 50A | 198 | 111 | 102 | 40 | 157 | 100 | 482.5 | 207 | 160 | 140 | 200 | 168 | 12×14 | 12 | 167.5 | 42 |

| 65FSD37Z | 3.7 | 65A | 50A | 216 | 111 | 102 | 40 | 157 | 112 | 480 | 186 | 190 | 140 | 220 | 168 | 12×14 | 12 | 186.5 | 52 |

TFD

Applications

- For hot oil supply

Features

- Long mechanical seal lifetime through the special

- gland packing and cooling fins design

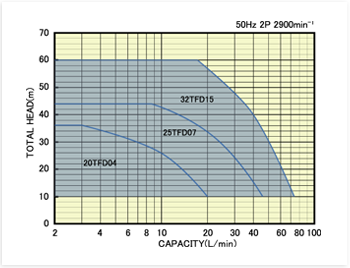

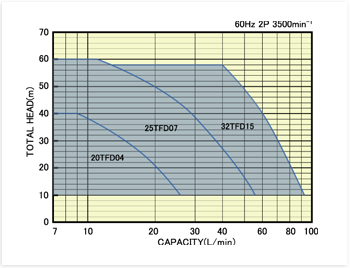

Performance Curve

Specification

| Series name |

TFD | |||

| Total head | Max. 60 m | |||

| Flow rate | Max. 90 L/min | |||

| Liquid temp. | ~ 2300 ℃ (for hot oil only) | |||

| Connection | JIS B 2291 Hydraulic flange 210 kgf/cm2 | |||

Material

| Casing / cover | FCD450 | |

| Impeller | FCD450 | |

| Mech. seal | SiC – Carbon, FKM | |

| O-ring | Special packing | |

| Motor | 50Hz 200V, 60Hz 200V/220V IP44, Insu. class: F/PSE |

|

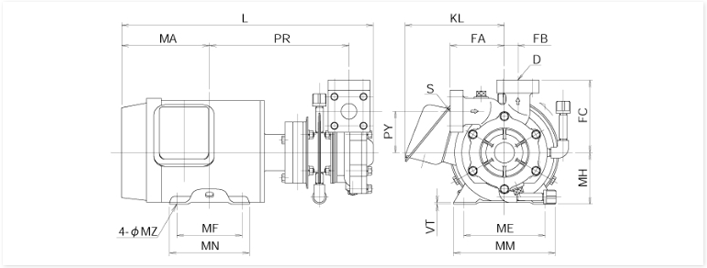

Dimensions

| Model | kW | S・D | PR | PY | FA | FB | FC | MH | L | MA | ME | MF | MM | MN | MZ | VT | KL | Weight |

| 20TFD04A | 0.56 | 20A | 192 | 57 | 75 | 18.5 | 100 | 71 | 346 | 121 | 112 | 90 | 140 | 110 | 7×8 | 2.3 | 175 | 15 |

| 25TFD07A | 0.975 | 25A | 188.5 | 68 | 85 | 23 | 110 | 80 | 361.5 | 133 | 125 | 100 | 155 | 125 | 10 | 8 | 181 | 28 |

| 25TFD15A | 1.95 | 25A | 211.5 | 68 | 85 | 23 | 110 | 90 | 410 | 158.5 | 140 | 125 | 176 | 150 | 10 | 10 | 195 | 35.5 |

| 32TFD15A | 1.95 | 32A | 215 | 76 | 100 | 28 | 130 | 90 | 411.5 | 158.5 | 140 | 125 | 176 | 150 | 10 | 10 | 195 | 36.5 |

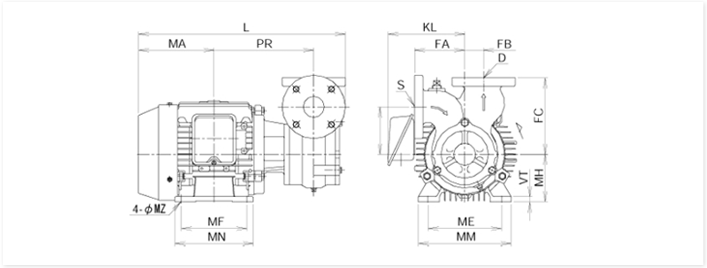

J Series

JLD / JHD

Applications

- General industrial applications

- Integrated with a variety of OEM machines

- Pure water and chemical liquid supply

- Industrial cleaning machines

- Food and beverage, pharmaceutical and medical

Features

- Prevent contamination due to the compact size and simple structure of these pumps.

- Regenerative turbine pumps achieve high pressure using a single stage impeller even without high speed rotatio

- The contact area between the pump and media is minimized resulting in a clean flow.

- Due to the simple structure with minimal holding volume and surface contact area bacterial contamination is minimized as

- well as reduced leaching of irons from metal parts to ppm levels

Minimal routine maintenance of consumables

-

Maintenance cost can be drastically reduced as there are no high wear consumable parts requiring

frequent replacements such as with bellows and diaphragm pumps which parts are subject to repeated

bending stress as well as internal check valves.

Stable performance

-

Unlike bellows and diaphragm pumps there is no pulsation, resulting in a stable liquid flow rate

for enhanced equipment and process performance.

SiC x special carbon mechanical seal (-J) option available for pure water (low-viscosity liquid) applications

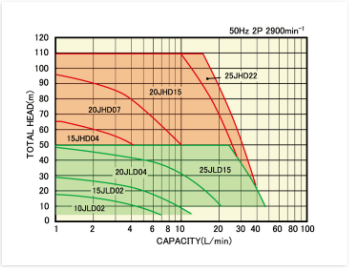

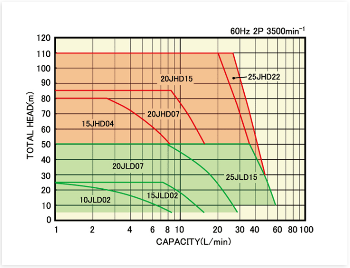

Performance Curve

Specification

| Series name |

JLD Standard (-J) | JHD Standard (-J) | ||

| Total head | Max. 50 m | Max. 110 m | ||

| Flow rate | Max. 60 L/min | |||

| Liquid temp. | ~ 90 ℃ (Standard) | |||

| Connection | Rc thread | |||

Material

| Series | JLD (-J) | JHD (-J) |

| Casing / cover | SS304 | |

| Impeller | SS304 | |

| Mechanical seal | SiC – SiC, PTFE (Standard) SiC – Carbon, PTFE (-J) |

|

| O-ring | PTFE | |

| Shaft | SS316L | |

Motor data

| Single phase / Open drip proof motor |

50Hz/60Hz: 100/110/115/200/220/230V 0.3~0.56kW IP22, Insu. class: E.PS-E | |

| Three phase / Total enclosed fan cooled motor |

50Hz: 200V 60Hz: 200/220V 0.15~0.56kW IP22, Insu. class: E.PS-E | |

| Three phase increased safety motor (A) |

50Hz: 200V 60Hz: 200/220V 0.3~2.42kW IP44, Insu. class: E.PS-E | |

| Model | kW | S | D | PR | PY | FA | FB | FC | MH | L | MA | ME | MF | MM | MN | MZ | VT | KL | Weight |

| 10JLD02Z | 0.31 | Rc 3/8 | Rc 3/8 | 146 | 9 | 44 | 9 | 44 | 71 | 294 | 121 | 112 | 90 | 140 | 110 | 7×8 | 2.3 | 107 | 11 |

| 15JLD02Z | 0.31 | Rc 1/2 | Rc 3/8 | 145 | 6 | 49.5 | 8 | 50 | 71 | 296 | 121 | 112 | 90 | 140 | 110 | 7×8 | 2.3 | 107 | 12.5 |

| 20JLD04Z | 0.56 | Rc 3/4 | Rc 1/2 | 142.5 | 7 | 53.5 | 9 | 54 | 71 | 297 | 121 | 112 | 90 | 140 | 110 | 7X8 | 2.3 | 107 | 15 |

| 20JLD07Z | 0.975 | Rc 3/4 | Rc 1/2 | 136 | 7 | 53.5 | 9 | 54 | 80 | 317.5 | 148 | 125 | 100 | 165 | 130 | 10×8 | 4.5 | 146 | 21.5 |

| 25JLD07Z | 0.975 | Rc 1 | Rc 3/4 | 132.5 | 6 | 63 | 9 | 63.5 | 80 | 318.5 | 148 | 125 | 100 | 165 | 130 | 10×8 | 4.5 | 146 | 26 |

| 25JLD15Z | 1.95 | Rc 1 | Rc 3/4 | 155.5 | 6 | 63 | 9 | 63.5 | 90 | 348 | 154.5 | 140 | 125 | 176 | 149 | 10×12 | 10 | 156 | 30 |

U Series

ULD / UPD

Applications

- General industrial applications

- Integrated with a variety of OEM machines

- Pure water and chemical liquid supply

- Washing solvent supply, suitable for filtration applications

Features

- Due to selection of material combinations (SUS304 / PTFE / SiC) can target variety of applications

- Very low noise levels silimar to centrifugal pumps, additional noise reduction measures not required

- Self-priming over 8 meters (25 feet)

- SiC x special carbon mechanical seal (model ULD-J) option available for pure water (low-viscosity liquid) applications

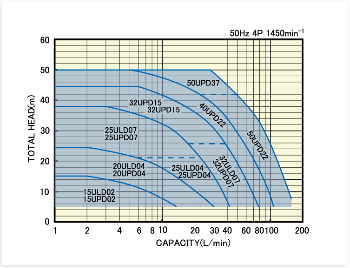

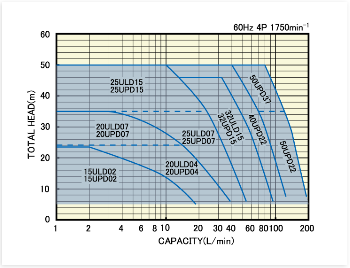

Performance Curve

Specification

| Series name | ULD – Standard | ULD-J | UPD (Self priming) |

| Total head | Max. 50 m | ||

| Flow rate | Max. 100 L/min | Max. 190 L/min | |

| Liquid temp. | ~ 90 ℃ | ||

Material

| Casing / cover | Lead-free copper | SCS14 |

| Impeller | SS304 | |

| Mechanical seal | SiC – Carbon | |

| O-ring | FKM | |

| Shaft | SS316 | |

Material

| Casing / cover | SCS13 | ||

| Impeller | SS304 | ||

| Mech. seal | SiC – SiC, PTFE | SiC – Carbon, PTFE | SiC – SiC, PTFE |

| O-ring | PTFE | ||

| Shaft | ODP & TEFC motor: SS316L Increased safety motor: SS304 |

||

Motor data

| Single phase Drip protection motor |

50Hz/60Hz : 100/110/115/200/220/230V 0.2~0.4kW IP22, Insu. class: E. PS-E |

|

| Three phase Total enclosed fan cooled motor |

50Hz : 200V 60Hz : 200/220V 0.2~3.7kW IP44, Insu. class : E. PS-E |

|

| Three phase increased safety (A) | 50Hz : 200V 60Hz : 200/220V 0.2~ 0.75kW IP44, Insu. class : E. PS-E |

|

Noize level: dB(A) at 50Hz frequency

| Model | During operation | JEM standard |

| 15ULD02Z |

55 | 59 |

| 20ULD04Z | 58 | 61 |

| 25ULD07Z | 59 | 63 |

| 32ULD15Z | 64 | 67 |

Self priming capability: min at 50Hz, water temperature 5 ℃

| Model | Suction head -4m | Suction head -8 m |

| 20UPD04Z | 4 | 5 |

| 25UPD07Z | 4 | 8 |

| 32UPD15Z | 2 | 4 |

| 40UPD22Z | 2 | 4 |

| 50UPD37Z | 2 | 4 |

| Model | kW | S・D | PR | PY | FA | FB | FC | MH | L | MA | ME | MF | MM | MN | MZ | VT | KL | Weight |

| 15ULD02Z | 0.2 | Rc 1/2 | 139.5 | 52 | 60 | 20 | 78 | 63 | 286 | 109 | 100 | 80 | 128 | 100 | 7×8 | 2.3 | 129 | 12 |

| 20ULD04Z | 0.4 | Rc 3/4 | 151 | 66 | 50 | 22 | 85 | 71 | 308 | 121 | 112 | 90 | 140 | 110 | 7×8 | 2.3 | 137 | 14 |

| 20ULD07Z | 0.75 | Rc 3/4 | 163 | 66 | 50 | 22 | 85 | 80 | 367 | 168 | 125 | 100 | 165 | 130 | 10×8 | 4.5 | 146 | 27.5 |

| 25ULD04Z | 0.4 | Rc 1 | 151.5 | 72 | 60 | 26 | 95 | 71 | 314 | 121 | 112 | 90 | 140 | 110 | 7×8 | 2.3 | 137 | 17 |

| 25ULD07Z | 0.75 | Rc 1 | 163.5 | 72 | 60 | 26 | 95 | 80 | 373 | 168 | 125 | 100 | 165 | 130 | 10×8 | 4.5 | 146 | 28.5 |

| 25ULD15Z | 1.5 | Rc 1 | 182 | 72 | 60 | 26 | 95 | 90 | 378 | 154.5 | 140 | 125 | 176 | 149 | 10×12 | 10 | 156 | 41.5 |

| 32ULD07Z | 0.75 | Rc 1/4 | 160 | 84 | 63 | 30 | 114 | 80 | 374 | 168 | 125 | 100 | 165 | 130 | 10×8 | 4.5 | 146 | 29 |

| 32ULD15Z | 1.5 | Rc 1/4 | 178.5 | 84 | 63 | 30 | 114 | 90 | 379 | 154.5 | 140 | 125 | 176 | 149 | 10×12 | 10 | 156 | 42 |